Brazing copper fittings is a crucial skill for many plumbing and HVAC professionals. This method of joining copper pipes ensures a strong, durable connection that can withstand high temperatures and pressures. In this article, we will delve into the intricacies of brazing copper fittings, providing expert advice and covering various related fittings and techniques.

Understanding Brazing and Its Importance

Brazing is a metal-joining process that involves melting a filler metal into the joint to bond two metal surfaces. Unlike soldering, which occurs at temperatures below 840°F, brazing requires higher temperatures, typically between 1,100°F and 1,500°F. This creates a stronger bond, making brazed fittings ideal for high-pressure and high-temperature applications.

Types of Brazed Fittings

Brazed fittings come in various forms, each designed for specific applications. Common types include:

- CSST Fittings: Corrugated stainless steel tubing fittings used for gas distribution.

- PEX Fire Sprinkler Fittings: Used in residential and commercial fire sprinkler systems.

- Toilet Flange Fitting: Connects the toilet to the drainpipe.

- Water Meter Connection Fittings: Links the water meter to the main water line.

- Frabo Fittings: Italian-made fittings known for their precision and reliability.

How to Braze Copper Fittings

Preparation

Before starting the brazing process, ensure you have the necessary tools and materials. You’ll need:

- Copper pipes and fittings

- Brazing rod

- Torch

- Flux

- Wire brush

- Safety equipment (gloves, goggles)

Steps to Braze Copper Fittings

Cleaning the Surfaces

The first step in brazing is cleaning the copper surfaces. Use a wire brush to remove any oxidation or debris. Clean surfaces ensure a stronger bond.

Applying Flux

Apply flux to both the pipe and the fitting. Flux helps prevent oxidation during heating and aids the flow of the filler metal.

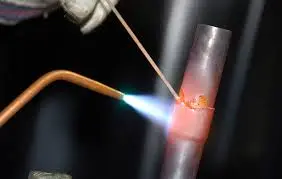

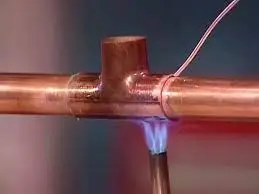

Heating the Joint

Using a torch, heat the joint evenly. Move the torch in a circular motion to distribute the heat uniformly. The temperature should be sufficient to melt the brazing rod but not so high that it damages the copper.

Adding the Filler Metal

Once the joint is heated, touch the brazing rod to the joint. The heat will melt the rod, allowing the filler metal to flow into the joint and bond the copper surfaces.

Cooling and Inspection

Allow the joint to cool naturally. Inspect the brazed joint for any gaps or weak points. A well-brazed joint should be smooth and free of any visible flaws.

Addressing Common Fitting Challenges

Pre Soldered Copper Fittings vs. Brazed Fittings

Pre-soldered copper fittings are convenient as they come with solder pre-applied inside the fitting. However, brazed fittings offer a stronger bond and are preferred for high-stress applications.

Dealing with an Uponor Fitting Shortage

The recent shortage of Uponor fittings has led many professionals to seek alternatives. Understanding different fitting options, such as Propex Brass Fittings and PEX AL PEX Fittings, can help navigate this shortage.

Using EZ Sweat Copper Fittings

EZ Sweat copper fittings are designed for easy installation, making them a popular choice for DIY projects. They require minimal tools and can be installed quickly, making them an excellent alternative to traditional brazed fittings.

Specialty Fittings and Their Uses

Elkhart Copper Fittings

Elkhart is renowned for its high-quality copper fittings. These fittings are used in various applications, from residential plumbing to industrial systems.

Nibco Copper Fittings

Nibco fittings are known for their durability and reliability. They are commonly used in both water supply and HVAC systems.

Quarter Bend Fitting

A quarter bend fitting, also known as a 90-degree elbow, is used to change the direction of the pipe. It is essential in plumbing systems to navigate around obstacles.

How to Remove Barbed Fitting from Poly Pipe

Removing a barbed fitting from a poly pipe can be challenging. Here’s a simple method:

- Heat the Area: Use a heat gun to warm the area around the fitting. This softens the poly pipe.

- Twist and Pull: Twist the fitting while pulling it out. The softened pipe should allow the fitting to come out with less resistance.

For More Visit: Copper Brazing Explained Everything You Need to Know

Conclusion

Brazing copper fittings is a skill that requires practice and precision. By understanding the different types of fittings and mastering the brazing process, you can ensure strong, reliable connections in your plumbing and HVAC systems. Whether dealing with common fittings like CSST and PEX fire sprinkler fittings or specialty ones like Elkhart and Nibco copper fittings, the knowledge gained from expert advice can significantly enhance your work quality.

Always prioritize safety and precision in your brazing projects, and stay informed about the latest advancements and best practices in the field.