Glass for a shower cabin is a material of exceptional strength with excellent aesthetic characteristics. It is in high demand, and the fashion for inexpensive models with plastic partitions is gradually becoming a thing of the past. Custom-made glass shower enclosures are considered an indicator of refined taste. If you wish, you can contact professionals who will develop a unique design and implement it. You need to make your choice responsibly since shower cabins occupy approximately ¼ of the entire room and perform an important task. They greatly influence the interior and functionality of the bathroom.

Glass For Shower Cabin

Why are showers made of glass?

When arranging a bathroom, plastic has shown its worst side. It relatively quickly loses its original appearance, becomes deformed under the influence of temperature changes, and gradually deteriorates. The most convenient and practical material is glass for showers. Among its advantages are:

- The shower cabin is made following the dimensions of the bathroom. Among the ready-made designs, many compact models are ideal when space is limited.

- Visual expansion of space and design value. Transparent walls will not clutter up the room or obscure it. Such showers adapt perfectly to different interior styles.

- No splashes indoors. When taking a shower, water will not flow outside of the shower. This is important for preserving equipment, furniture and decoration.

- Practicality. With the help of a good glass shower, you can free up usable space and properly zone the room.

- Durability. Glass retains its original appearance for a long time. It is wear-resistant, resistant to mechanical stress, high humidity and cleaning agents.

- No need for special care. Any dirt can be washed off the surface of the glass without much effort. It is enough to use a damp cloth and gentle household chemicals.

Glass shower screens remain transparent even after years of use. They fit harmoniously into any interior if you approach the design correctly.

Why are showers made of glass?

Basic requirements for glass

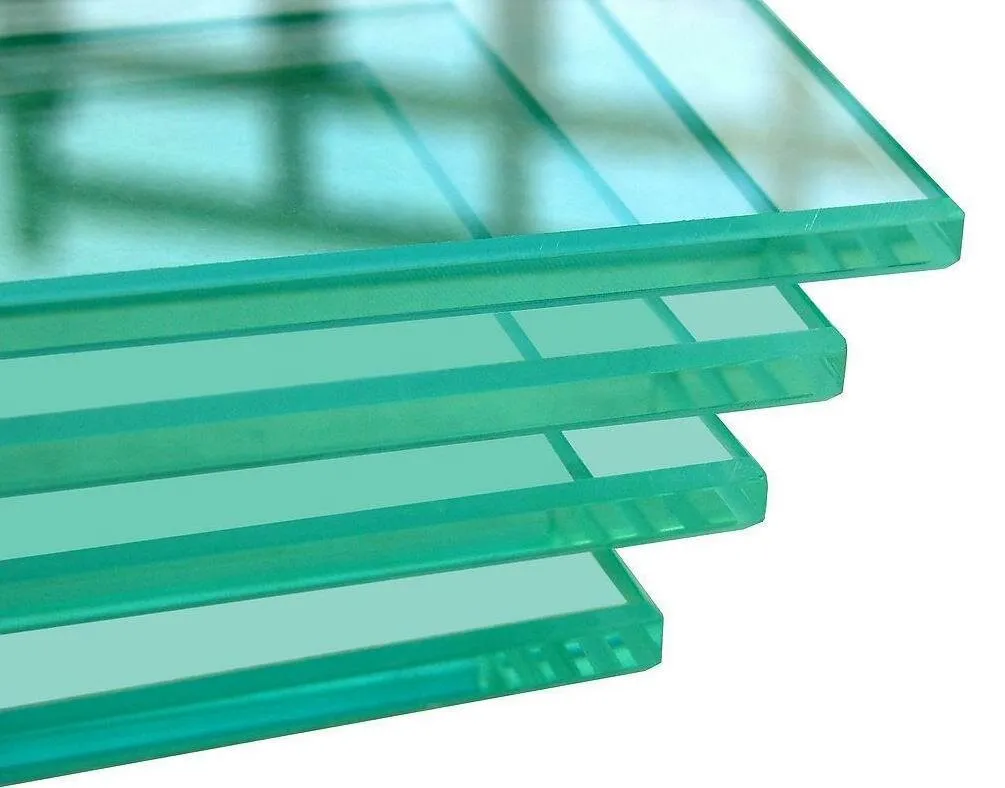

If you decide not to contact specialists but want to install a shower with clear or frosted glass yourself, then you need to take into account some important parameters. Depending on the thickness and manufacturing process, the product will have different characteristics. Ordinary glass, for example, is a poor option due to its fragility. On impact, it shatters into sharp fragments. The optimal solutions are tempered glass for showers or triplex. Each of them has individual properties.

Strained glass

If you have already become familiar with the characteristics and features of tempered glass, then you probably know that it is a durable material that can withstand intense loads. These properties are achieved by processing the material at a temperature of 650-680 degrees Celsius. Heating and sudden cooling allow you to achieve:

- maximum resistance to mechanical stress (strength increases approximately 7 times);

- resistance to bending;

- safety (in addition to the fact that breaking glass will require effort, if it is damaged, it will form rounded fragments rather than sharp ones).

Tempered glass is also chosen for showers because scratches and other defects do not appear on its surface. The material is resistant to water and steam. Valued for its high level of translucency. Also, fungus or mold does not appear on its surface.

Triplex

Triplex glass is a material in which 2 or more sheets are glued together. Between them, there is a transparent or matte film made of polymers. This design provides increased impact resistance and excellent noise insulation properties. Triplex is in demand due to:

- high strength and resistance to damage;

- heat conservation and protection from UV radiation;

- good sound insulation;

- resistance to mechanical damage (glass does not shatter when broken, but remains on the film).

Available in different colours. Can be processed in various ways.

Options

Glass for shower trays and partitions can be of different thicknesses, but 8 mm is most often chosen. Products 6 mm are not strong enough, and 10 mm are quite thick. The latter is used for showers in public places: fitness centres, SPA, etc.

Triplex

Processing Methods

When making glass shower cabins, different design approaches are used. Among the modern processing methods, the following stand out:

- Photo printing. It involves creating images on the glass surface using a special printer.

- Matting. The creation of opaque glass is carried out using sandblasting equipment or using special chemical reagents.

- Grinding. Diamond coating or wheel grinding is used here.

- Applying protective film or paint. Compositions characterized by water-repellent properties are selected.

- Ultraviolet gluing, fusing. Using these technologies, not just shower partitions are created, but real paintings that decorate the interior.

- Cutting. Technology is used to obtain the desired shape. This requires maximum precision to get the right size shower glass. The more accurately the parts are cut, the higher the tightness of the joints will be.

- Drilling. Required for making holes into which fittings are later installed.

- Bending. Using this technique you can make curved glass elements. It consists of heating the product in an oven. Then, when the material becomes more pliable, under its weight or external influence it is given a curved shape. To avoid internal stress, after heating the glass is cooled slowly. As a result, it takes on the desired shape and becomes stronger.

Hardening deserves special attention. This glass processing technology for shower cabins is used to achieve high strength.

Processing methods